The UH-1 ‘Iroquois’ is a light multirole utility and combat helicopter. Better known as the ‘Huey’ from its original ‘HU-1’ designation, the UH-1 is one of the world’s most iconic helicopters. A mainstay of U.S. forces in the Vietnam War, the Huey shot to fame following its starring roles in Hollywood blockbusters The Deer Hunter (1978) and Apocalypse Now (1979).

Known as a ‘slick’, the Huey’s primary mission was to insert and extract combat troops. Airborne assaults in Vietnam consisted typically of up to 10 slicks ferrying infantry, with two or three gunships providing protection and a ‘Charlie/Charlie’ Command and Control helicopter orbiting overhead. The Huey’s other missions included forward supply; search and rescue (SAR); reconnaissance and the medical evacuation (Medevac) of injured troops. The UH-1H can carry 4000 lbs of weapons & cargo including up to 14 combat troops or 6 stretchers. Armed with rockets and machine guns, it can also act as an ad hoc gunship.

Developed in the 1950s, the UH-1 entered service in March 1961. The UH-1H with the uprated 1,400 shp (1,000 kW) Lycoming T53-L-13 is the most-produced variant of the 16,000-plus that have been built since then. The Huey continues to serve worldwide in both military and civilian roles.

The DCS: UH-1H features an updated model of the helicopter armed with rockets and door-mounted M134 six-barrel rotary miniguns. The simulation offers superb flight and systems modeling. Helpful Easy Flight and other modes reduce the learning curve for new players. Player positions include pilot, co-pilot, and door gunners. A handcrafted storyline campaign is included as well as a number of single missions and a training course.

A robust and trustworthy work-horse, the UH-1 evokes enormous affection from former crews. When you fly it, you will immediately understand why.

The UH-1 Huey is one of the most iconic and recognizable helicopters in the world. Having served extensively as a transport and armed combat support helicopter in the Vietnam War, the Huey continues to perform a wide variety of military and civilian missions around the world today.

"DCS: UH-1H Huey" features an incredible level of modelling depth that reproducers the look, feel, and sound of this legendary helicopter with exquisite detail and accuracy. Developed in close partnership with actual UH-1H operators and experts, the DCS Huey provides the most dynamic and true to life conventional helicopter experience available on the PC.

A variety of realism and gameplay options, a number of single missions and a handcrafted campaign storyline featuring custom voiceovers and characters provide ample fun and immersion for both the realism buff and the casual enthusiast.

"DCS: UH-1H Huey" is the first DCS title to offer multiple player positions, including pilot, co-pilot, and door gunner. The helicopter can be flown as either a lightly armed combat transport or a close air support platform armed with steerable rapid-firing machine guns and unguided rockets.

A comprehensive training course that includes both demonstration lessons and in-cockpit interactive tutorials designed with the help of real helicopter pilots takes you through the learning process of proper helicopter control and employment.

A powerful yet easy-to-use mission editor allows you to create an unlimited number of both single-player and multiplayer missions and campaigns. A one-click Mission Generator also allows you to instantly create battles as small or large as you wish.

Fly online using the built-in server browser and fight with or against other player-controlled DCS aircraft like the Ka-50 Black Shark, P-51D Mustang and A-10C Warthog in a rich multiplayer environment.

Key Features of "DCS: UH-1H Huey" include:

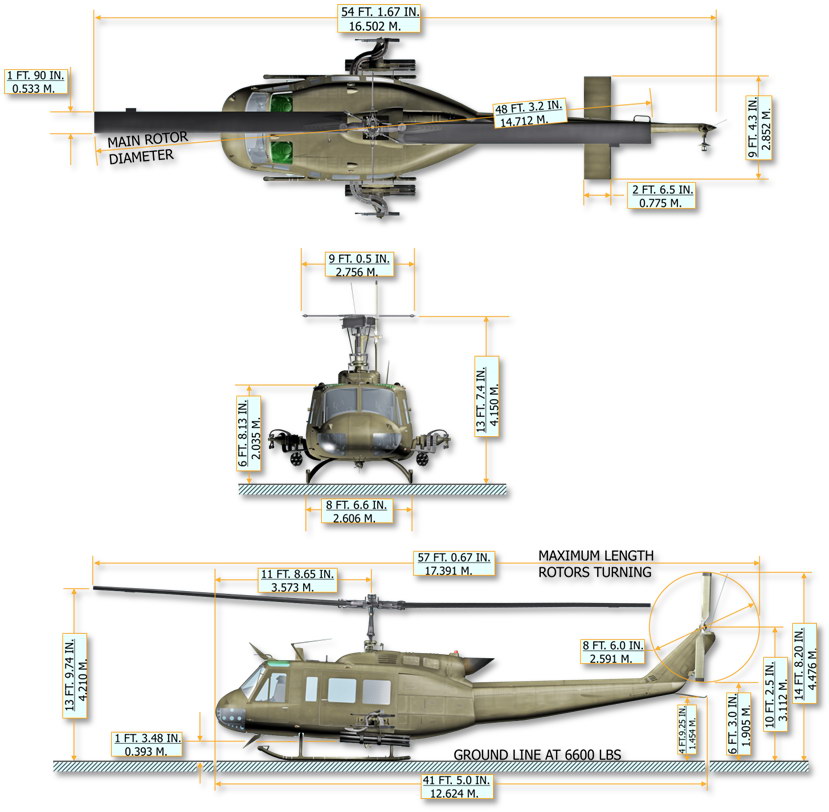

The UH-1H is a single engine, single rotor helicopter. Primary mission capability of the helicopter is air movement of supplies and personnel. Secondary missions include air assault, and command and control (C2) operations under day, night, visual, and instrument conditions.

In DCS: UH-1H Huey, the helicopter can be operated in the following variants:

The helicopter can be employed either from prepared airfields or Forward Area Rearming/Refueling Point (FARP) helipads.

The crew includes the pilot in the right-hand seat, copilot in the left-hand seat and one or two door gunners.

Helicopter velocity is determined using primitive equations that calculate the forces and moments not only at the fuselage center of gravity (CG), but also acting on the turning rotors, which include the flapping motions of the rotor blades. This makes it possible to model all of the dynamic effects specific to helicopter flight.

The aerodynamic forces acting on the helicopter model are derived as a summation of the parameters of its individual elements: main and tail rotors, fuselage, vertical fin, horizontal stabilizer, pylons, landing skids. Each of these elements is positioned and orientated individually within the airframe’s local coordinate system and has its own aerodynamic characteristics.

The aerodynamic characteristics of each model element are pre-calculated with special software using numerical methods. In determining the forces and moments acting on the main and tail rotors, the calculations include the axial and longitudinal components of airflow speed, blade pitch, rotor angular velocities, airflow parameters, and blade inertia characteristics.

The aerodynamic forces acting on each model element are determined according to its pre-calculated characteristics in its own coordinate system. This includes local airflow velocity changes in the vicinity of the element as induced by other model elements.

Each element has a damage/destruction capacity that affects the lifting and center of gravity calculations of the model. Damage can be affected either by aerodynamic force or by physical contact with the ground or other objects. Ground and object contact is modeled using a system of rigid body points.

The detailed, real-time modeling of the dynamics involved with the main and tail rotors, fuselage, empennage, and other elements of the helicopter produces flight characteristics that closely match those of the real Huey and make it possible to naturally induce and closely model important flight conditions and effects like torque-induced yaw, translational lift, translating tendency, rotor overspeed and droop, retreating blade stall, autorotation, settling with power (vortex ring state), etc.

DCS: UH-1H Huey features an accurate and highly detailed 3D model of the helicopter using a 100,000+ polygon construction and a variety of historically accurate and inspired high resolution liveries. Multiple-texture maps, normal maps and specular maps are used to achieve a variety of special effects while extensive use of skeletal animation is made for effects such as rotor blade flexing, skid flexing, and machine gun belt bending.

The main rotor assembly is fully animated and correctly translates movement of the cyclic and collective controls to the rotor system, making it possible to visually see rotor disc tilting, conning, and blade pitching. Tail rotor pitch is animated and correctly translates anti-torque pedal input to the tail rotor.

The model includes extensive damage visualization that includes sector-based bullet/shrapnel penetration, canopy/window fracturing and penetration, and variety of partial or complete tearing of aircraft sections.

Many custom audio samples of actual UH-1 sounds were taken specifically for this project by a number of UH-1 operators and affiliates in an effort to faithfully represent and immerse the player in the audio environment of the helicopter. Inside and outside the cockpit, the sound environment is filled with handcrafted audio that includes the main rotor, tail rotor, engine components, various cockpit systems, and weapons.

DCS: UH-1H Huey features an accurately reproduced, highly detailed and interactive 3D cockpit with six-degrees-of-freedom ("6DOF") technology that allows the player to move the viewpoint in any direction inside the cockpit space. This means you can not only look up, down, left and right, but also raise or lower your viewpoint, slide to either side, move closer or further from the instrument panel, and even tilt left or right.

Nearly all of the onboard systems of the helicopter are animated and functional, allowing the player to configure the systems in the cockpit by either using the mouse to click on the desired switches and controls or by using keyboard shortcuts that can be mapped to the player’s HOTAS.

The cockpit includes two color schemes – black and light grey, depending on the selected livery. For low light/night operations, fully adjustable internal lighting is available and includes two flood lights and a number of panel and instrument light controls.

The front instrument panel includes the primary flight indicators, engine instruments and a number of other indicators.

The Central Pedestal is positioned between the two pilots and contains a number of control panels to operate the radio systems, armament systems, engine fuel flow, force trim, and others. All of these controls are fully animated and functional in DCS: UH-1H Huey with the single exception of the transponder set, which is animated and can be configured, but has no function in the simulation.

The Caution Lights Panel is subsystem of the Master Caution System and is used to indicate caution and warning signals to the pilot.

The Overhead Console contains controls for internal and external lighting, electrical power, and others. All of these controls are fully animated and functional in DCS: UH-1H Huey with the single exception of the Cabin Heating control panel, which is animated and can be configured, but has no function in the simulation.

The flight control system is a hydraulically-assisted positive mechanical type, actuated by conventional helicopter controls. Complete controls are provided for both pilot and copilot. The system includes a cyclic system, collective control system, tail rotor system, force trim system, synchronized elevator, and a stabilizer bar.

The system is operated by the cyclic stick movement. Moving the stick in any direction will produce a corresponding movement of the helicopter which is a result of a change in the plane of rotation of the main rotor. The pilot cyclic contains the cargo release switch, radio ICS switch, armament fire control switch, hoist switch and force trim switch. Desired operating friction can be induced into the control stick by hand tightening the friction adjuster.

The synchronized elevator is located on the tailboom. It is connected by control tubes and mechanical linkage to the fore-and-aft cyclic system. Fore-and-aft movement of the cyclic control stick will produce a change in the synchronized elevator attitude. This improves controllability within the center of gravity (cg) range.

The stabilizer bar is mounted on the main rotor hub trunnion assembly in a parallel plane, above and at 90 degrees to the main rotor blades.

The gyroscopic and inertial effect of the stabilizer bar will produce a damping force in the rotor rotating control system and thus the rotor. When an angular displacement of the helicopter/mast occurs, the bar tends to remain in its trim plane. The rate at which the bar rotational plane tends to return to a position perpendicular to the mast is controlled by the hydraulic dampers. By adjusting the dampers, positive dynamic stability can be achieved, and still allow the pilot complete responsive control of the helicopter.

The collective pitch control lever controls vertical flight. When the lever is in full down position, the main rotor is at minimum pitch. When the lever is in the full up position, the main rotor is at maximum pitch. The amount of lever movement determines the angle of attack and lift developed by the main rotor, and results in ascent or descent of the helicopter. Desired operating friction can be induced into the control lever by hand-tightening the friction adjuster. A grip-type throttle and a switch box assembly are located on the upper end of the collective pitch control lever. The pilot switch box contains the starter switch, governor rpm switch, engine idle stop release switch, and landing light/searchlight switches. A collective lever down lock is located on the floor below the collective lever. The copilot collective lever contains only the grip-type throttle, governor rpm switch, and starter switch when installed. The collective pitch control system has built-in breakaway (friction) force to move the stick up from the neutral (center of travel) position of eight to ten pounds with hydraulic boost ON.

The tail rotor control system is operated by pilot/copilot anti-torque pedals. Pushing a pedal will change the pitch of the tail rotor blades, resulting in directional control. Pedal adjusters are provided to adjust the pedal distance for individual comfort. A force trim system is connected to the directional controls.

Force centering devices are incorporated in the cyclic controls and directional pedal controls. These devices are installed between the cyclic stick and the hydraulic servo cylinders, and between the anti-torque pedals and the hydraulic servo cylinder. The devices furnish a force gradient or "feel" to the cyclic control stick and anti-torque pedals. A FORCE TRIM ON/OFF switch is installed on the miscellaneous control panel to turn the system on or off. These forces can be reduced to zero by pressing and holding the force trim push-button switch on the cyclic stick or moving the force trim switch to OFF.

The power system of the UH-1H consists of a single Textron Lycoming T53-L-13B turboshaft engine with a maximum output power of 1100kW/1400 hp.

The fuel control assembly is mounted on the engine. It consists of a metering section, a computer section and an overspeed governor.

The metering section is driven at a speed proportional to N1 speed. It pumps fuel to the engine through the main metering valve or if the main system falls through the emergency metering valve which is positioned directly by the twist grip throttle.

The computer section determines the rate of main fuel delivery by biasing main metering valve opening for N1 speed, inlet air temperature and pressure, and throttle position. It also controls the operation of the compressor air bleed and operation of the variable inlet guide vanes.

The overspeed governor is driven at a speed proportional to N2 speed. It biases the main metering valve opening to maintain a constant selected N2 RPM.

Rotating the pilot or copilot twist grip-type throttle to the full open position allows the overspeed governor to maintain a constant RPM.

Rotating the throttle toward the closed position will cause the rpm to be manually selected instead of automatically selected by the overspeed governor. Rotating the throttle to the fully closed position shuts off the fuel.

An idle stop is incorporated in the throttle to prevent inadvertent throttle closure. To bypass the idle detent press the IDLE REL switch and close the throttle.

The GOV switch is located on the ENGINE control panel. AUTO position permits the overspeed governor to automatically control the engine rpm with the throttle in the full open position. The EMER position permits the pilot or copilot to manually control the rpm. Because automatic acceleration, deceleration, and overspeed control are not provided with the GOV switch in the EMER position, control movements must be smooth to prevent compressor stall, overspeed, over-temperature, or engine failure.

Note. If GOV switch is in EMER position and throttle is full opened, main rotor rpm can exceed the limit, so pilot should control engine and rotor rpm manually by rotating the throttle twist grip.

The system consists of an engine oil tank with deaeration provisions, thermostatically controlled oil cooler with bypass valve, pressure transmitter and pressure indicator, low pressure warning switch and indicator (see Caution Lights Panel), sight gauges and oil supply return vent and breather lines. Pressure for engine lubrication and scavenging of return oil are provided by the engine mounted and engine driven oil pump.

The pilot and copilot GOV RPM INCR/DECR switches are mounted on a switch box attached to the end of the collective pitch control lever. The switches are a three-position momentary type and are held in INCR (up) position to increase the power turbine (N2) speed or DECR (down) position to decrease the power turbine (N2) speed.

A droop compensator maintains engine RPM (N2) as power demand is increased by the pilot. The compensator is a direct mechanical linkage between the collective stick and the speed selector lever on the N2 governor. No crew controls are provided or required. The compensator will hold N2 RPM to 340 RPM when properly rigged. Droop is defined as the speed change in engine rpm (N2) as power is increased from a no-load condition. It is an inherent characteristic designed into the governor system. Without this characteristic instability would develop as engine output is increased resulting in N1 speed overshooting or hunting the value necessary to satisfy the new power condition.

The power train is a system of shafts and gear boxes through which the engine drives the main rotor, tail rotor, and accessories, such as the DC generator and the hydraulic pump. The system consists of a main drive shaft, a main transmission, which includes input and output drives, and the main rotor mast, and a series of drive shafts with two gear boxes through which the tail rotor is driven.

The main transmission is mounted forward of the engine and coupled to the power turbine shaft at the cool end of the engine by the main driveshaft. The transmission is basically a reduction gearbox, used to transmit engine power at a reduced rpm to the rotor system. A freewheeling unit is incorporated in the transmission to provide a quick-disconnect from the engine if a power failure occurs. This permits the main rotor and tail rotor to rotate in order to accomplish a safe auto-rotational landing. The tail rotor drive is on the lower aft section of the transmission. Power is transmitted to the tail rotor through a series of driveshaft and gearboxes. The rotor tachometer generator, hydraulic pump, and main DC generator are mounted on and driven by the transmission. A self-contained pressure oil system is incorporated in the transmission. The oil is cooled by an oil cooler and turbine fan. The engine and transmission oil coolers use the same fan. The oil system has a thermal bypass capability. An oil level sight glass, filler cap, and magnetic chip detector are provided. A transmission oil filter is mounted in a pocket in the upper right aft corner of sump case, with inlet and outlet ports through internal passages. The filter incorporates a bypass valve for continued oil flow if screens become clogged. The transmission external oil filter is located in the cargo-sling compartment on the right side wall, and is connected into the external oil line. On Helicopters equipped with the Oil Debris Detection System (ODDS), a full flow debris monitor with integral chip detector replaces the integral oil filter. A bypass valve is incorporated, set to open at a set differential pressure to assure oil flow if filter element should become clogged.

Normal revolution (min-1): main rotor (mast): 324, tail rotor: 1782.

The armament system of the DCS UH-1H consists of the M23 and M21 subsystems.

The M23 armament subsystem is attached to the external stores hardpoint fittings on both sides of the helicopter. The M-60D flexible 7.62 millimeter machine guns are free pointing but limited in traverse, elevation, and depression by cam surfaces and stops on pointless and pintle post assemblies of the two mount assemblies on which the machine guns are mounted. An ejection control bag is latched to the right side of each M60D machine gun to hold the spent cases, unfired rounds and links. Cartridges travel from ammunition box and cover assemblies to M60D machine gun through flexible chute and brace assemblies (machinegun).

The M21 armament subsystem consists of two M134 6x barrel 7.62mm high rate machine guns and two 7 tube (M158) or 19 tube (M159) 2.75 inch aircraft rocket launchers.

The M134 guns are steerable and can be traversed in azimuth and elevation by aiming using the left pilot’s flexible sighting station.

The guns can also be fired by the right pilot in Stow mode using the XM60 infinity sight, in which case they remain boresighted in the forward position.

With gun mounts in the Stow position, the electric drive assembly motor will only receive enough voltage to drive the gun at a rate of 2400 shots per minute. When moving the mounts through the field of deflection, one mount must stop at its inboard limit. Upon reaching the inboard limit, the gun will cease to fire and the opposite gun will accelerate to 4000 shots per minute; therefore, with both guns operational, the constant rate of fire is 4800 rounds per minute. This rate can be reduced to 2400 rounds per minute by selecting one gun (left or right) with the GUN SELECTOR switch on the control panel.

The UH-1H can employ a wide variety of 2.75 inch Hydra 70 rockets using either the XM158 seven-tube launchers or XM159 19-tube launchers. The Hydra 70 has evolved into a wide array of air-to-surface aerial rockets. All of the 2.75 inch Folding Fin Aerial Rockets (FFAR) in this simulation use the MK66 rocket motor. FFAR rockets are an area effect weapon and are certainly not a precision attack weapon. Common targets for most of the rocket warheads include un-armored or lightly armored targets and they can be useful as a suppression weapon.

DCS: UH-1H Huey includes the following warhead options for 2.75 inch rockets for use with the Huey: